The report finds that the current position of quality products in this company are quite good but there is still can be improve so that a better products can be formed along with a low cost needed. All the details about the process are being explained in the discussion later based on the diagrams shown. In addition, there are flow diagram and piping and instrumentation diagram (PNID) done in order to make the process crystal clear. All calculations and formulas are shown in the result and discussion.

Other calculations include overall mass balance of the raw material and the products, the heat absorbed and lost during the process, work input and output by calculating the machines' efficiency and lastly the overall energy balance in the injection molding process. Mainly, the method of analysis of the balances is in spreadsheet programming. Therefore, this company has been reducing the demands of thermoplastic goods around Sarawak.This report provides an analysis and evaluation of the mass and energy balance on injection molding process in this factory, which is located at Kuching, Sarawak. What benefits can be obtained from this company towards civilization? The major benefits is the production of good quality of preform plastic bottles which then are being sends to other oil company all over Sarawak. Basically, injection molding process is a process where the plastic granules or pellets are being melted down and shaped and being cooled down through plasticisation process. In order to have this product, there must be an injection molding process. One of them is a preform PET bottle production factory, a small factory in Kuching. Hence, there is thousands of company that has been running a business on this product around the world. Furthermore, experts prefer single-stage process usually just for manufacturing custom bottle designs in limited numbers, where economies of scale could not be achieved.The demanding of thermoplastics as consumer goods have increasingly high since a decade ago due to its capability that is better than glass. The single-stage is more suited where producing blemish-free, sturdy threaded and the oblong-shaped bottle is a priority, otherwise two-stage are preferred for optimum price economy. Moreover, other key determining factors include particulars of the application with reference to bottle features and economics. In addition, the number of preforms for the two-stage reheat machine has significantly increased over the past decade, since preforms are much more cost-effective to ship globally than the bottles. The figure of 2 million pieces/year is important since most custom applications are produced less than this number. The difference in capital costs involved in both the process can be explained by the fact that investing even in a four-cavity single-stage is not feasible with reference to volumes under 2 million/year, compared to investing in sourcing preforms for a two-cavity reheat machine. There are certain factors crucial for the process selection these include tool prices, overall capital expenditure and the number of available performs, etc. Whereas, the remaining 15-20% were manufactured where either process is an option. com), out of which nearly 80% were utilized for beverages and commonly manufactured using the two-stage technology. In this regard, it is important to know that the world consumed over 580 billion plastic bottles in 2021(Statista. Generally, blow molding processes are characterized by a number of stages involved in the process (i.e., single-stage and double-stage, etc.) the choice is usually based on the type of product/application. The "cold preform method" derives its name from the requirement to chill preform prior to actually reheating and stretching.įigure 3: PET Two-Stage Automatic Blow Molding Machine How Two-Stage Molding is better than One-Stage When they arrive, they are unscrambled, reheated with infrared light, and conditioned before molding. The preform will typically include the bottle's neck including and its threads also, it can be transferred to a third - party vendor before being inflated out using second machine. In the first machine, the plastic is injected into a totally cooled preform before being delivered to the second device. The injection molding method and stretch blow molding machine are examples of these.

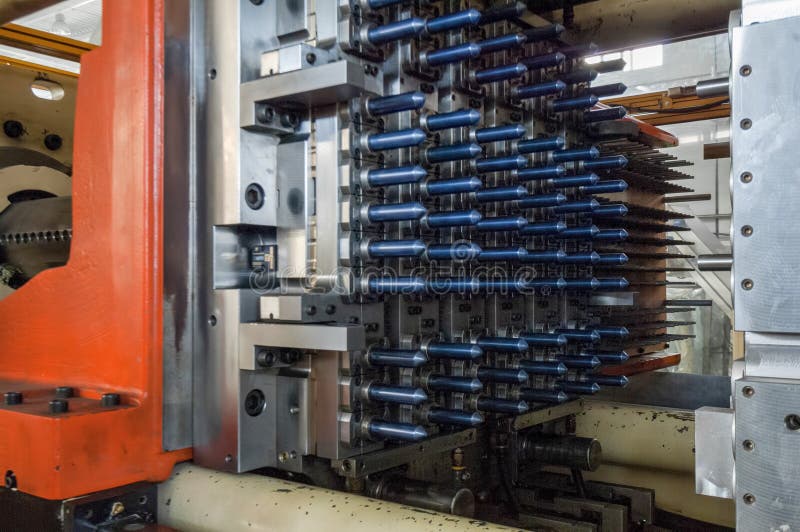

Two machines are utilized in the two-stage injection extension blow molding procedure. The raw material is injected from the hopper into the injection screw the plate spins preform to the blow/stretch blow terminal with its own heat, and with no heating up for blowing the product then rotates to the release station and drops down it is completely automated circulation working method.

There are three stations on the machines: injection way to strengthen, stretch or blow, and product. Figure 1: Working of One-Stage Pet Molding Machine

0 kommentar(er)

0 kommentar(er)